Our Projects

Precision Engineering and Production of High-Performance Camshafts

Design and production of high-precision camshafts using advanced materials, CAD modeling, and surface hardening processes to ensure accurate valve timing, wear resistance, and long-term engine reliability.

Introduction

The camshaft, a critical component in internal combustion engines, precisely controls the timing and movement of intake and exhaust valves through cam lobes, playing a key role in regulating the intake of fuel-air mixture and the expulsion of exhaust gases, ensuring optimal performance, power delivery, and engine efficiency. This complex component, designed with precision engineering and advanced manufacturing techniques, actuates valve train components to open and close valves at precise intervals, withstanding high rotational speeds and mechanical stresses to deliver exceptional reliability and performance in vehicles and industrial machinery.

Material Selection

The selection of raw materials for the camshaft is critical due to its exposure to high contact stresses and wear during valve actuation. High-strength steel alloys, such as chrome-molybdenum steels, are commonly used for their excellent hardness, fatigue resistance, and ability to endure cyclic loads, making them ideal for high-performance engines. For cost-effective applications, such as light-duty vehicle engines, chilled cast iron or nodular cast iron is preferred for its superior wear resistance on cam lobes and lower cost. At Noor Powertrain Company, we prioritize product quality by meticulously selecting materials that closely match the original camshaft’s performance and mechanical properties, ensuring compatibility with advanced manufacturing processes.

Redesign & Manufacturing

The camshaft manufacturing process begins with precise design using CAD software, where a detailed 3D model is developed, often derived from enhanced point cloud data obtained via 3D scanning for reverse engineering or prototyping. Engineering drawings adhere to stringent GD&T standards, focusing on the precise geometry of cam lobes responsible for valve lift, duration, and timing. The initial shaping process is selected based on supply chain management and customer requirements, choosing from forging, casting, or billet machining. Forging is employed for high-performance camshafts to achieve a robust grain structure, while chilled casting is common for cost-effective production. Effective supply chain management ensures high-quality raw materials and timely coordination with suppliers to prevent production delays. Customer specifications, such as valve timing precision and performance metrics, guide material and process selection to meet global standards.

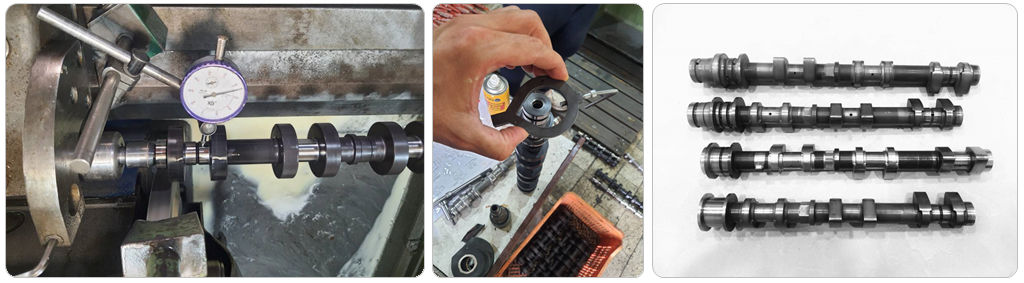

After initial shaping, the camshaft undergoes precision machining to achieve final dimensions and smooth surfaces, with a particular focus on cam lobe profiles, which require specialized grinding techniques to ensure accurate valve timing. Main journals are machined to tight tolerances (in the micron range) to minimize friction and ensure smooth rotation. Oil passages are drilled to lubricate bearing surfaces, critical for enhancing component durability.

To withstand intense contact stresses from valve train components and enhance wear resistance, camshafts undergo heat treatment processes such as induction hardening, carburizing, or nitriding, while the core retains ductility to resist dynamic stresses. Carburizing is used for steel camshafts to create a hard, wear-resistant surface layer, while chilled casting enhances lobe hardness in cast iron camshafts. At Noor Powertrain Company, we have achieved excellent performance test results by employing both nitriding and induction hardening for surface hardening, demonstrating the high quality and durability of our products. This process is essential for ensuring long-term reliability in high-performance or heavy-duty engines.

Quality Control

Quality control is paramount for the camshaft, as it directly impacts engine timing and efficiency. The Coordinate Measuring Machine (CMM) is a cornerstone of our quality assurance process, providing precise dimensional and geometric inspections. Non-destructive testing methods, such as ultrasonic testing, complement CMM to detect internal defects like cracks or voids. Our rigorous quality control process ensures that camshafts meet global standards for performance, durability, and reliability.

Conclusion

The camshaft production process at Noor Powertrain Company combines meticulous material selection, advanced CAD design, and precision manufacturing techniques to produce camshafts with exceptional accuracy, durability, and performance. Our expertise in crafting precise cam lobe profiles and implementing rigorous quality control with tools like CMM ensures compliance with global standards. Through reverse engineering and localization, this process demonstrates Noor Powertrain Company’s ability to deliver high-quality, competitive camshafts in the global automotive industry, establishing us as a reliable and efficient partner.