Our Projects

Combustion, Gas Exchange, and Performance Analysis

Advanced simulation and real-world testing of a 4000 cc V6 engine to optimize combustion, gas exchange, and overall performance.

Introduction

This project is dedicated to advancing the understanding and improving the performance of powertrains, specifically focusing on a V6, 4000 cc engine. It achieves this by comprehensively simulating combustion and gas exchange processes, complemented by rigorous experimental performance testing. Recognizing the inherent complexities of modern powertrain systems, our integrated approach, combining empirical data with advanced computational modeling, enables a precise, validated and in-depth analysis of engine behavior across diverse operating conditions. This research is vital for automotive manufacturers seeking to create optimized, highly efficient, and environmentally friendly designs that reduce emissions.

Methodology

The methodology for this project is systematically structured into two primary sections: Experimental Testing and Advanced Modeling & Simulation.

A. Tests

Experimental tests are meticulously performed to gather real-world data on the engine's performance, which is crucial for the subsequent validation and refinement of our simulation models. These comprehensive tests encompass:

- Engine Motoring Test:A detailed motoring test report, specifically documenting the in-cylinder pressure as a function of crank angle.

- Combustion Test: A comprehensive combustion test report, including pressure analysis as a function of crank angle, and in-cylinder pressure at full load across the entire crank angle

- Performance Test: A thorough performance test report, presenting key metrics such as power, torque, and fuel consumption curves.

- Gas Exchange Tests: A detailed gas exchange test report, covering essential parameters like air filter pressure drop, valve lift profiles, the performance of the variable valve timing system, precise volumetric efficiency measurements, intake manifold pressure measurements, and the extraction of discharge coefficients.

B. Modeling and Simulation

Modeling and simulation efforts are undertaken to provide a deeper analytical insight into the underlying physical phenomena and to accurately predict engine performance under a wide range of operating scenarios. This section leverages specialized and industry-standard software, including GT-Suite, CATIA, ANSYS Fluent, and CONVERGE CFD.

- Exporting of One-Dimensional Gas Exchange Path Model: Development of a one-dimensional gas exchange path model within GT-Suite software. This model is meticulously constructed based on the precise three-dimensional geometry of the gas exchange paths, as designed in CATIA, and validated against available technical reports to ensure accuracy.

- One-Dimensional Combustion Analysis: A comprehensive report on the one-dimensional combustion analysis conducted in GT-Suite software. This includes: the determination of maximum in-cylinder pressure and the corresponding crank angle of maximum pressure at full load across various engine speeds, calculation of Wiebe parameters based on assumed ignition timing, analysis of the mass fraction burned due to combustion, and detailed heat release rate diagrams for various speeds and loads.

- One-Dimensional Gas Exchange Analysis: A detailed report on the one-dimensional gas exchange analysis performed in GT-Suite software. This encompasses: in-cylinder pressure at each crank angle during motoring conditions, quantification of air pressure drop across the throttle valve at various speeds and loads, measurement of intake air pressure and temperature, Variable-length intake manifold (VLIM), exhaust gas pressure and temperature, volumetric efficiency, mass flow rate of air to each cylinder, and exhaust gases from each cylinder. Furthermore, it includes an in-depth analysis of the variable intake valve timing system, and the one-dimensional pressure and temperature distribution along the gas exchange path.

- Three-Dimensional Gas Exchange Analysis: A comprehensive report on the three-dimensional gas exchange analysis. This analysis is based on the precise three-dimensional combustion chamber model developed in CATIA and includes: the distribution of pressure and velocity of the fluid within the intake and exhaust manifolds, the pressure and velocity distribution of the fluid inside the cylinder during both intake and exhaust processes, and the pressure and velocity distribution within the intake and exhaust ports. Crucially, it also involves the extraction of in-cylinder swirling flow characteristics (swirl and tumble) using ANSYS Fluent software.

- Predictive Combustion Modeling – SI Turbulence: A detailed report on the predictive combustion modeling using the SI Turbulence model within GT-Suite software. This report covers: maximum in-cylinder pressure at full load across various engine speeds, the crank angle of the maximum pressure point at full load across various speeds, Wiebe parameters derived from assumed ignition timing, the mass fraction burned due to combustion at each crank angle for both full and partial load conditions, heat release rate diagrams for full and partial load conditions, and the utilization of the three-dimensional combustion chamber model. A key aspect is the calibration to match maximum pressure and maximum pressure angle, along with an analysis of knocking probability at various speeds and loads.

- One-Dimensional Model Integration: A report on the integration of the one-dimensional models, providing a holistic view of engine performance. This includes: power, torque, volumetric efficiency, and brake specific fuel consumption curves. It also details the interactive performance of all interconnected systems, including gas exchange, combustion, cooling, and lubrication.

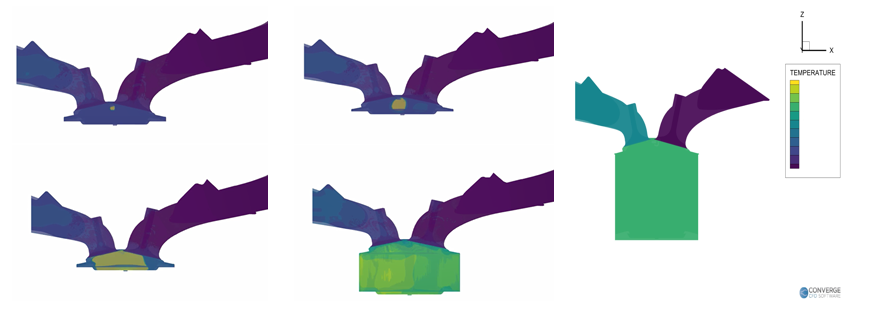

- Open Cycle Combustion Three-Dimensional Analysis: A report on the open cycle combustion analysis, conducted using CONVERGE CFD software. This analysis provides: in-cylinder pressure at each crank angle (p-theta diagram), in-cylinder temperature at each crank angle (T-theta diagram), predicted emission rates resulting from combustion under various engine operating conditions, and the heat release rate at each crank angle.

Results

The results generated from this comprehensive project will provide a profound and integrated understanding of powertrain performance across multiple dimensions. Through the rigorous experimental tests, accurate and highly reliable data on the actual engine behavior will be obtained, serving as an indispensable foundation for validating and refining the simulation models. The sophisticated one-dimensional and three-dimensional modeling techniques will enable a detailed and granular analysis of both combustion and gas exchange processes, thereby facilitating the identification of optimal performance points and the proactive detection of potential issues.

Specifically, the anticipated results include:

- Accurate Performance Data: Precise power, torque, and fuel consumption curves, which are fundamental for a thorough evaluation of the engine's overall performance characteristics.

- Deep Combustion Insights: In-depth information regarding in-cylinder pressure and temperature, the rate of heat release, and the probability of knocking. These insights are absolutely vital for the effective optimization of the combustion process.

- Comprehensive Gas Exchange Analysis: Detailed data on pressure drop, volumetric efficiency, and the intricate in-cylinder flow characteristics (such as swirl and tumble). This information is instrumental in significantly improving the design of both the intake and exhaust systems.

- Emission Prediction: Crucial information concerning predicted emission rates, which is essential for ensuring compliance with stringent environmental standards and for the development of cleaner, more sustainable engines.

- Integrated and Validated Models: The creation of robust simulation models, rigorously validated against experimental data. These models will serve as powerful and indispensable tools for future powertrain design, development, and optimization efforts.

These comprehensive results will empower powertrain R&D companies to leverage deep technical knowledge and cutting-edge simulation tools, fostering innovation in engine design while simultaneously reducing the time and cost associated with product development.