Our Projects

Dynamic and Kinematic Analysis of Engine Components

Stress, fatigue, and motion analysis of key V6 engine parts to improve durability, reduce vibration, and ensure smooth mechanical operation.

Introduction

This project focuses on the comprehensive dynamic and kinematic analysis of critical engine components within the V6, 4000 cc powertrain. Understanding the forces, stresses, vibrations, and movements of these components is essential for ensuring their structural integrity, optimizing their performance, and extending the overall durability of the engine. By integrating advanced mechanical and vibrational analyses with kinematic modeling, this project aims to provide a detailed insight into the operational behavior of the engine's moving parts under various conditions.

Methodology

The methodology for the Dynamic and Kinematic Analysis project primarily involves advanced mechanical (solid mechanics and vibrational) analyses and kinematic modeling, leveraging industry-standard software such as Abaqus and GT-Suite.

A. Mechanical Analyses (Solid Mechanics and Vibrational)

These analyses are conducted to assess the structural integrity, stress distribution, and vibrational characteristics of key engine components. The following specific analyses are performed:

- Crankshaft Vibration Analysis:

A detailed analysis of crankshaft vibrations to understand and mitigate potential resonance issues and ensure smooth engine operation. - Thermal Stress Analysis of Piston, Block, and Cylinder Head:

An in-depth analysis of thermal stresses experienced by the piston, cylinder block, and cylinder head, crucial for predicting component longevity and preventing thermal fatigue. - Stress Analysis of Block, Cylinder Head, Main Bearing Caps, and Connecting Rod:

Comprehensive stress analysis performed on the cylinder block, cylinder head, main bearing caps, and connecting rod to identify high-stress areas and optimize their design for durability. - Fatigue Analysis of Connecting Rod, Gudgeon Pin, and Main Bearings:

Low-cycle and high-cycle fatigue analyses conducted on the connecting rod, gudgeon pin (piston pin), and main bearings to predict their operational lifespan under cyclic loading. - Exhaust Manifold Temperature Analysis (Temperature and Thermal Stress Distribution):

Analysis of the exhaust manifold's temperature distribution and associated thermal stresses, vital for preventing material degradation and ensuring efficient exhaust gas flow. - Low-Cycle Fatigue Analysis of Cylinder Head:

Specific low-cycle fatigue analysis for the cylinder head, addressing stresses from repeated thermal cycles. - High-Cycle Fatigue Analysis of Crankshaft:

High-cycle fatigue analysis for the crankshaft, critical for evaluating its long-term durability under continuous engine operation.

B. Kinematic Modeling and Analysis

Kinematic modeling focuses on the motion and interaction of engine components without considering the forces that cause the motion.

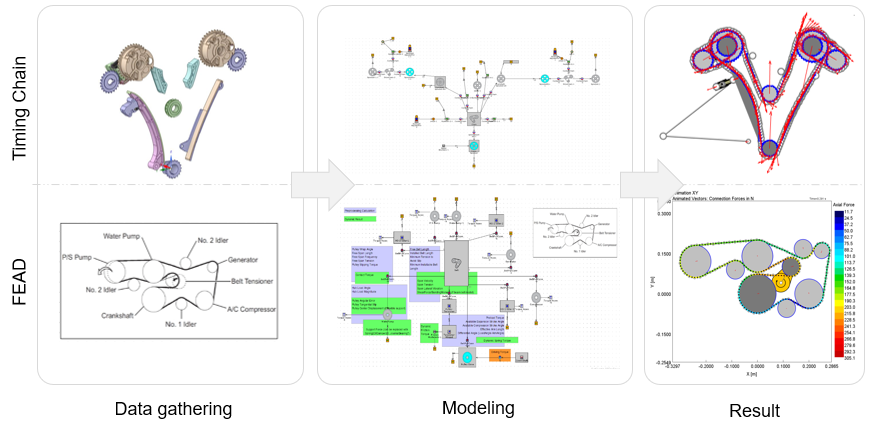

- Kinematic Modeling of Camshaft, Crankshaft, and Timing Assembly:

Detailed kinematic modeling of the camshaft, crankshaft, and the entire timing assembly to understand their precise movements and synchronization. - Analysis of Forces on Crank Assembly and Bearings:

An in-depth analysis of the forces exerted on the crank assembly, including both main and connecting rod bearings, to ensure proper lubrication and prevent wear. - FEAD Mechanism Analysis (Belt/Chain Tension and Conditions):

Analysis of the Front End Accessory Drive (FEAD) mechanism, focusing on belt or chain tension and overall operating conditions to ensure reliable power transmission to accessories. - Cam Profile Design and Analysis:

Design and analysis of the valve cam profiles using GT-Suite software, optimizing valve lift, duration, and timing for improved engine performance and gas exchange.

Results

The results derived from this Dynamic and Kinematic Analysis project will provide a profound and integrated understanding of the mechanical behavior and motion of the engine's critical components. Through the rigorous analyses, accurate and highly reliable data on the actual stresses, vibrations, and kinematic interactions will be obtained, serving as an indispensable foundation for optimizing component design and ensuring long-term engine reliability.

Specifically, the anticipated results include:

- Optimized Component Durability: Identification of critical stress points and fatigue life predictions for components like the connecting rod, gudgeon pin, and bearings, leading to design improvements for enhanced durability.

- Vibration Mitigation: Comprehensive analysis of crankshaft vibrations, enabling design modifications to reduce noise, harshness, and vibration (NVH) and improve engine smoothness.

- Enhanced Thermal Management of Exhaust Manifold: Detailed temperature and thermal stress distributions for the exhaust manifold, guiding design improvements to prevent heat-related failures.

- Improved Kinematic Performance: Precise kinematic models of the camshaft, crankshaft, and timing assembly, allowing for optimization of valve timing and overall engine efficiency.

- Validated FEAD System Performance: Analysis of FEAD mechanism, ensuring optimal belt/chain tension and conditions for reliable accessory drive operation.

- Advanced Cam Profile Design: Optimized valve cam profiles leading to improved gas exchange efficiency and overall engine performance.

These comprehensive results will empower automotive manufacturers to leverage deep technical knowledge and cutting-edge simulation tools, fostering innovation in engine component design while simultaneously enhancing durability, performance, and overall engine reliability.