Our Projects

Lubrication System Analysis

From simulation-driven analysis to tailored lubrication strategies, this project highlights our expertise in optimizing thermal and mechanical performance of transmission systems.

Introduction

This project is dedicated to a comprehensive analysis of the lubrication system within the V6, 4000 cc powertrain. An efficient and robust lubrication system is fundamental for minimizing friction, managing heat, and ensuring the long-term durability and optimal performance of engine components. This project integrates experimental lubrication and friction tests with advanced one-dimensional modeling and analysis to provide a detailed understanding of the lubrication circuit's behavior and its impact on overall engine efficiency.

Methodology

The methodology for the Lubrication System Analysis project is structured into two main components: Lubrication and Friction Tests, and One-Dimensional Lubrication and Friction Analyses.

A. Lubrication and Friction Tests

Experimental tests are meticulously performed to gather real-world data on the lubrication system's characteristics and friction losses, which are crucial for the subsequent validation and refinement of our simulation models. These tests include:

- Lubrication and Friction Tests:

A detailed report on lubrication and friction tests, specifically documenting: the characteristic curve of the oil filter, the characteristic curve of the oil pump, the volumetric flow rate of oil in the main oil gallery (for validation purposes), Variable valve timing (VVT) actuator, oil pressure and temperature within the lubrication circuit, and the frictional mean effective pressure (FMEP) of the engine in combustion mode (for validation purposes).

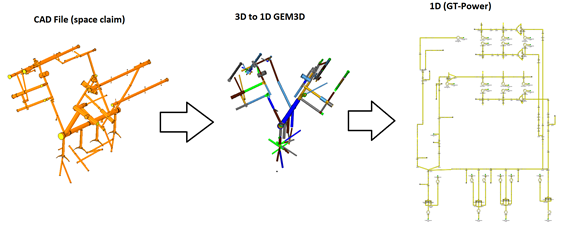

B. One-Dimensional Lubrication and Friction Analyses

One-dimensional modeling and analysis efforts are undertaken to provide a deeper analytical insight into the lubrication and friction phenomena and to accurately predict the lubrication system's performance across various operating scenarios. This section leverages industry-standard software such as GT-Suite, FLOW MASTER, and AVL.

- One-Dimensional Lubrication and Friction Analyses:

A comprehensive report on the one-dimensional lubrication and friction analyses performed using GT-Suite, FLOW MASTER, and AVL software. This includes: the volumetric balance (contribution of each consumer) within the lubrication circuit at various engine speeds, oil pressure within the lubrication circuit (at bearings, piston cooling jets, chain tensioners, the furthest point from the oil pump in the cylinder head, and variable valve timing system) at various engine speeds, forces exerted on the crankshaft and connecting rod bearings at various engine speeds and full load conditions, oil film thickness in the crankshaft, connecting rod, and camshaft bearings at various engine speeds and full load conditions, the total frictional mean effective pressure (FMEP) for the entire crank assembly, piston, main and connecting rod bearings, valves, and timing chain in motoring mode, and the engine's frictional mean effective pressure in combustion mode.

Results

The results derived from this Lubrication System Analysis project will provide a profound and integrated understanding of the engine's lubrication system performance and its contribution to overall frictional losses. Through rigorous experimental tests, accurate and highly reliable data on the actual behavior of the lubrication circuit and frictional characteristics will be obtained, serving as an indispensable foundation for validating and refining the simulation models. The sophisticated one-dimensional modeling techniques will enable a detailed and granular analysis of oil flow, pressure distribution, and friction, thereby facilitating the identification of optimal lubrication strategies and the proactive detection of potential issues.

Specifically, the anticipated results include:

- Accurate Lubrication System Data: Precise measurements of oil filter and pump characteristics, oil flow rates, and pressure and temperature distributions within the lubrication circuit, fundamental for evaluating the system's efficiency.

- Deep Frictional Insights: In-depth information regarding the frictional mean effective pressure of various engine components and the total engine, crucial for identifying areas of high friction and optimizing designs for reduced mechanical losses.

- Comprehensive Oil Flow Analysis: Detailed data on volumetric balance and oil pressure at critical points within the lubrication circuit, instrumental in ensuring adequate lubrication to all components and preventing oil starvation.

- Optimized Bearing Performance: Analysis of oil film thickness and forces on bearings, leading to design improvements for enhanced bearing durability and reduced wear.

- Integrated and Validated Lubrication Models: The creation of robust lubrication simulation models, rigorously validated against experimental data. These models will serve as powerful and indispensable tools for future powertrain lubrication system design, development, and optimization efforts.

These comprehensive results will empower automotive manufacturers to leverage deep technical knowledge and cutting-edge simulation tools, fostering innovation in engine lubrication system design while simultaneously enhancing durability, performance, and fuel efficiency.