Our Projects

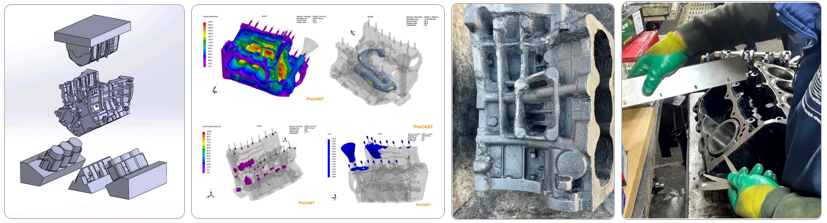

Comprehensive Analysis and Manufacturing of V-Type Cylinder Blocks

Design and manufacturing of high-precision V-type cylinder blocks using aluminum alloys and cast iron to ensure optimal engine performance, durability, and compliance with global standards.

Introduction

The cylinder block is a fundamental and critical component in internal combustion engines, serving as the structural foundation for housing cylinders, pistons, crankshaft, and other engine components. This part must withstand the pressures from combustion, high temperatures, and severe mechanical stresses while also supporting cooling, lubrication, and power transmission to the crankshaft. The V-type cylinder block, due to the angled arrangement of cylinders, is more complex than inline blocks, requiring high precision in design and manufacturing to ensure dynamic balance, effective cooling, and optimal engine performance. These blocks are widely used in high-performance vehicles and heavy-duty engines that demand high torque and efficiency. At Noor Powertrain, we have gained valuable expertise in manufacturing this type of cylinder block.

Material Selection

For cylinder block production, materials with high strength, wear resistance, and suitable heat transfer properties are selected. Gray cast iron is a common choice for standard engines due to its excellent wear resistance, castability, and low cost. For high-performance engines, aluminum alloys (such as series 3000, 6000, or hypereutectic alloys) are preferred due to their lighter weight and superior heat transfer, despite higher costs. Material selection is based on customer requirements, industry standards, and manufacturing processes.

Design

The manufacturing process of V-type cylinder blocks begins with reverse engineering or initial design using 3D scanning and CAD modeling. The digital model is designed with strict adherence to GD&T standards, focusing on the precision of cylinder geometry, cooling channels, cylinder head attachment points, and the exact V-angle configuration. Given Noor Powertrain’s expertise in manufacturing both aluminum and cast iron cylinder blocks, the material type influences design modifications, such as wall thickness and rib complexity. Additionally, cast iron liners in aluminum blocks are of the dry type (encased within the aluminum block structure), while in cast iron blocks, they are of the wet type (in direct contact with cooling channels). A summary of the differences between these two designs is provided in the table below:

| Feature | Cast Iron Block | Aluminum Block |

|---|---|---|

| Wall Thickness | Thicker, due to inherent strength | Thinner, with reinforcing liners |

| Rib Complexity | Simpler, fewer ribs | More complex, extensive network |

| Vibration Absorption | High (less need for ribs) | Low (requires more ribs) |

| Heat Transfer | Moderate | Excellent |

| Weight | Heavier | Lighter |

| Production Cost | Lower | Higher (due to design and liners) |

Manufacturing

The initial manufacturing process varies depending on the material and customer requirements. Casting: For aluminum blocks, die casting is commonly used due to its ability to produce complex shapes with high precision and smooth surfaces. Molten aluminum is injected into metal molds under pressure. For cast iron blocks, sand casting is employed due to its lower cost and flexibility for larger shapes. After casting, parts undergo cleaning and removal of excess material. CNC Machining from Billet: For prototyping or low-volume production of aluminum or steel blocks, CNC machining from a solid block is used. This method offers high precision but is costly and time-consuming, limiting it to prototypes or niche applications. Effective supply chain management ensures the timely availability of high-quality raw materials and coordination with suppliers to avoid production delays.

Precision Machining

After initial forming, the V-type cylinder block undergoes multiple stages of CNC machining to achieve precise dimensional and geometric tolerances. Key operations include drilling and honing cylinder walls for accurate piston fit, milling cylinder head mating surfaces, and creating cooling and lubrication channels. The precise V-angle and uniformity of cylinder walls are critical for maintaining dynamic balance. Cylinder bores are honed to reduce friction and extend service life.

Quality Control

To ensure compliance with global standards, V-type cylinder blocks undergo comprehensive inspections. These include measurements with CMM devices to verify geometric tolerances, radiographic testing to detect internal defects in cast samples, and tensile and hardness tests to confirm compliance with the specified cast iron grade. Hardness testing also verifies the effectiveness of any heat treatment applied. Statistical analysis of production batches ensures consistent quality and reliability.

Conclusion

Noor Powertrain’s expertise in redesigning and localizing critical engine components, combined with precise material selection (such as aluminum alloys and gray cast iron), manufacturing aligned with effective supply chain management, adherence to global standards, and rigorous quality control, ensures optimal performance and reliability in advanced automotive engines. Noor Powertrain remains committed to producing reliable V-type cylinder blocks for the automotive industry through a focus on quality and innovation.