Our Projects

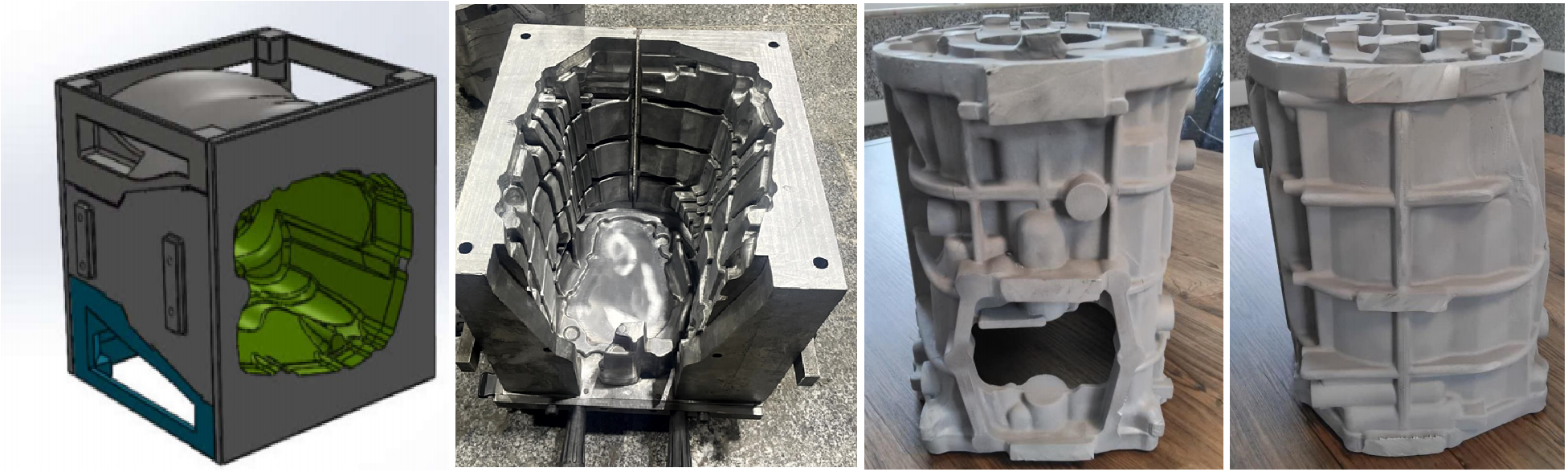

Redesign and Manufacturing of Gearbox Housing Using Advanced Reverse Engineering Techniques

Complete reverse engineering and prototyping of a gearbox housing using precision casting and advanced QC—delivering optimized design and seamless functionality.

Introduction

One of our most notable achievements in the field of industrial component design and manufacturing is the reverse engineering and production of a gearbox housing. This project aimed to redesign and reproduce the gearbox casing using reverse engineering techniques and advanced investment casting technology, with the goal of delivering a high-quality product with optimized performance.

By combining technical expertise, innovative design, and modern manufacturing methods, we successfully developed a product with superior quality, high dimensional accuracy, and enhanced functionality, demonstrating our capability in producing complex industrial components.

With a team of skilled engineers and technical experts, we are committed to strengthening domestic capabilities through reverse engineering, design for production (DFP), and advanced manufacturing techniques.

Analysis and Redesign

The original gearbox housing was thoroughly analyzed to extract its technical specifications, dimensions, and material characteristics. Using advanced 3D scanning, a highly detailed digital model was created, capturing all features essential for proper gearbox operation.

This model was then mechanically optimized using specialized design software to maintain performance while improving structural integrity and efficiency. As a result, the redesigned component featured a more reliable and efficient design compared to the original.

Manufacturing

For production, we utilized investment casting, which enabled the fabrication of a component with exceptional dimensional accuracy, a smooth surface finish, and minimal common casting defects such as porosity or cracking.

By selecting high-quality alloys and implementing precise process control, the final product achieved excellent mechanical strength, hardness, and surface integrity. The uniform and polished surface made the housing ideal for seamless gearbox assembly and reduced internal friction.

Quality Control & Testing

Stringent quality control measures were applied throughout all production stages, using tools such as Coordinate Measuring Machines (CMM) to verify micron-level dimensional accuracy. The finished housing underwent a series of destructive and non-destructive tests, including hardness and mechanical strength evaluations, microstructural examination, and radiographic testing (RT) for internal defect detection. In addition, the housing was subjected to leak testing to verify its sealing integrity and ensure the absence of surface cracks or internal porosity, which are critical for components exposed to lubricants or internal pressure. These evaluations confirmed that the final component not only matched the original but also outperformed it in several key performance metrics. By selecting high-quality alloys and implementing precise process control, the final product achieved excellent mechanical strength, hardness, and surface integrity. The uniform and polished surface made the housing ideal for seamless gearbox assembly and reduced internal friction.