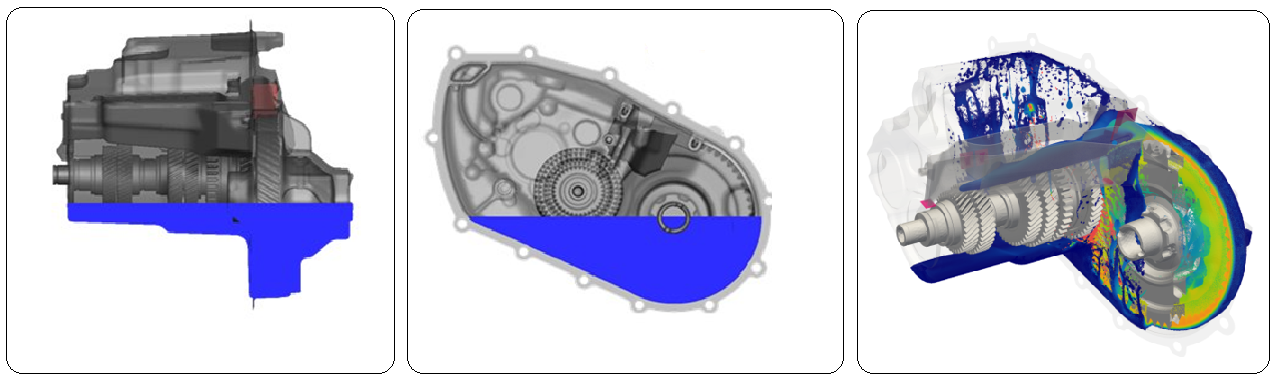

Lubrication and Cooling Analysis

Analysis in an Automotive Transmission System

From simulation-driven analysis to tailored lubrication strategies, this project highlights our expertise in optimizing thermal and mechanical performance of transmission systems.

Project Overview

The performance and durability of powertrain components in vehicles operating under diverse conditions—such as off-road environments—largely depend on effective lubrication and thermal management strategies, especially when exposed to dynamic load, terrain, and temperature variations. In this project, a comprehensive engineering assessment was conducted to evaluate the lubrication mechanisms and cooling performance of an off-road vehicle’s main gearbox and its transfer case. The goal was to identify optimal lubrication solutions tailored to the mechanical demands and internal configuration of each unit.

By combining technical expertise, innovative design, and modern manufacturing methods, we successfully developed a product with superior quality, high dimensional accuracy, and enhanced functionality, demonstrating our capability in producing complex industrial components.

With a team of skilled engineers and technical experts, we are committed to strengthening domestic capabilities through reverse engineering, design for production (DFP), and advanced manufacturing techniques.

Lubrication Strategy for Main Gearbox

The main gearbox—responsible for handling the majority of torque multiplication and speed reduction tasks—features a relatively complex architecture with a high number of gear meshes in simultaneous engagement. Due to the thermal and mechanical loads generated in such systems, a forced oil circulation lubrication method is employed. In this approach, oil is actively pumped under pressure and routed through specific channels to lubricate gears, bearings, synchronizers, and rotating shafts. This ensures uniform distribution of lubricant across all critical surfaces and enhances cooling by carrying heat away from the contact zones.

This method is commonly used in medium- to high-duty transmission systems where the heat generation is non-negligible and where precise control over oil delivery improves operational stability. It also supports better performance under start-stop driving and high-RPM conditions by maintaining consistent film thickness and preventing dry contacts during transitions. However, the system involves added complexity due to pumps, channels, filters, and seals, and may require closer attention to maintenance and oil quality over time.

Lubrication Strategy for Transfer Case

In contrast, the transfer case—although regularly active—operates with fewer gear engagement modes and a less crowded internal layout. For this reason, it utilizes a splash lubrication or oil bath method, where components are partially submerged in lubricant and rotation-induced motion causes oil to be flung onto surrounding parts. This technique is simpler, more passive, and widely used in transfer cases, differentials, and lightweight transmissions with limited heat buildup and fewer synchronized shifts.

Splash lubrication is advantageous in systems with fewer friction pairs, moderate duty cycles, and well-contained housings. It avoids the need for auxiliary components like pumps and pressure sensors. That said, its performance is more sensitive to oil level, viscosity, and component geometry. If the oil level is too low or gear geometry doesn’t allow proper splashing, some contact areas may be under-lubricated, especially during extended operation at low speeds or extreme inclines.

Simulation-Based Analysis and Recommendations

This study developed and evaluated lubrication strategies customized for the transient mechanical and thermal loads of off-road duty cycles, using simulation-based analysis to model oil distribution, flow behavior, and system responsiveness under real-world conditions. The study examined oil flow distribution, heat dissipation capacity, and the role of design features such as oil guide channels, dampers, and cavity shaping in promoting effective lubrication. Recommendations included using high-viscosity multipurpose gear oils (e.g., SAE 75W-90 and MP-type oils), ensuring proper oil level monitoring, and considering oil behavior across seasonal temperature ranges.

The finished housing underwent a series of destructive and non-destructive tests, including hardness and mechanical strength evaluations, microstructural examination, and radiographic testing (RT) for internal defect detection. In addition, the housing was subjected to leak testing to verify its sealing integrity and ensure the absence of surface cracks or internal porosity, which are critical for components exposed to lubricants or internal pressure.

These evaluations confirmed that the final component not only matched the original but also outperformed it in several key performance metrics. By selecting high-quality alloys and implementing precise process control, the final product achieved excellent mechanical strength, hardness, and surface integrity. The uniform and polished surface made the housing ideal for seamless gearbox assembly and reduced internal friction.

Conclusion

By aligning lubrication strategies with the unique structural and functional characteristics of each gearbox, this project contributed to the development of more robust and maintainable transmission systems suitable for harsh environments.